Operator messages are displayed on the terminal to inform about the current status on the station and the carrier in the work position.

Here are the common messages and what they mean.

Not Logged In

Station cannot be used since there is not an operator logged in. Log in with the terminal command

Login in a user on the terminal. If a password is set on the account, the user will be asked to input it.

| username | Username |

Empty Work Position

When the configured work position does not contain any carrier.

If the terminal additionally states 'Carrier Misread' on the second line, this indicates that there is a carrier in the station reader that cannot be read.

Pushing the operator switch again will retry reading the carrier. If the carrier repeatedly does not read, contact maintenance to check the carrier or station reader for issues.

Unknown Carrier

The carrier in work position could not be read by the station reader. The RFID tag may be broken, or the station reader faulty.

It is possible to manually tell the system what carrier is in the work position by keying in a terminal command

Note

This should not happen after Ingenious 1.14 and firmware 4.48.30, instead the carrier will stay in the station reader (see Empty Work Position).

Send Carrier On

The carrier in work position does not have any operation to perform at this station and should be sent away.

Enter Order Number

This message is displayed on loading stations when a carrier without a product arrives. The carrier should be assigned to an order line using the terminal command

Loads order to the carrier in working position

The quantity of the carrier will be set to the default of the loaded article.

| orderNumber | Order Number |

| orderLineNumber | Order Line Number |

Already Loaded

This is the equivalent of Send Carrier On, but only shown on a loading station. The carrier in work position does not have any operation to perform, but in this case the operator may choose to instead assign a different product to that carrier with a new loading command.

Messages After Operator Switch

If the operator has pressed the switch, but the carrier does not leave, this may be either due to a Station Lock or Routing Error.

Operation Messages

When there is an ongoing operation on the carrier in work position, an operation message will be displayed. This message should show the relevant information that the operator needs to know to perform the operation.

Operation messages can be configured in three places, globally, by setting the System Setting, by setting it on the Operation Group, or on the Operation itself.

The more specific messages override the less specific ones.

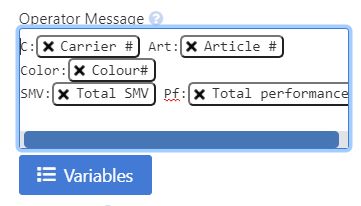

The message can be configured by using the Operation Message Editor

Plain text can be combined with a number of variables to create a message. Remember that the terminal display is limited to 3 lines with 16 characters on each line, any more than that will be cropped and will not show up on the screen.

After configuring a message, the editor may look something like this

The variables that can be used are

Article ➡ #/carrier

The number of products that the carrier contains.

Article ➡ Article

The article number of the product.

Carrier Id

Number of the carrier.

Criteria ➡ [Criteria Type]

The Criteria value for the chosen Criteria Type.

Custom ➡ [Custom Field]

This option is available if custom fields have been defined on article, product, order etc.

Operation ➡ Operation Name

Name of the ongoing operation.

Operation ➡ PieceRate

The configured piece rate for the operation in progress.

Operation ➡ Route Name

Name of the route that the carrier is currently on.

Operation ➡ Route Type

The Route Type of the route the carrier is currently on.

Operation ➡ Route Type (1 char)

R = Repair

I = Inspect

P = Production

Operation ➡ SMV

SMV value for the current operation.

Operator Status ➡ ...

Every subordinate variable is scoped to current logged in user.

Operator Status ➡ Logged in user

Name of logged in user.

Operator Status ➡ Operation count

Count of completed operations of current operation type.

Operator Status ➡ Operation faults

Count of caused faulty operations of current operation type.

Operator Status ➡ Operation minutes

Minutes spent in On or Off Standard work mode on current operation type, ongoing operation included.

Operator Status ➡ Operation off standard

Minutes spent in Off Standard work mode on current operation type, ongoing operation included.

Operator Status ➡ Operation on standard

Minutes spent in On Standard work mode on current operation type, ongoing operation included.

Operator Status ➡ Operation performance

Operator performance on current operation type, calculated by the following formula:

Operation performance = Operator Status ➡ Operation SMV / Operator Status ➡ Operation on standard

Operator Status ➡ Operation piece rate

Earned piece rate for current operation type.

Operator Status ➡ Operation SMV

Earned SMV for current operation type.

Operator Status ➡ Total efficiency

Total efficiency, calculated by the following formula:

Total efficiency = Operator Status ➡ Total SMV / Operator Status ➡ Total minutes

Operator Status ➡ Total faults

Total count of caused faulty operations.

Operator Status ➡ Total minutes

Total minutes spent in On or Off Standard work mode, ongoing operation included.

Operator Status ➡ Total off standard

Total minutes spent in Off Standard work mode, ongoing operation included.

Operator Status ➡ Total on standard

Total minutes spent in On Standard work mode, ongoing operation included.

Operator Status ➡ Total operation count

Total count of completed operations.

Operator Status ➡ Total paused

Total minutes spent in Pause work mode, ongoing operation included.

Operator Status ➡ Total performance

Total performance, calculated by the following formula:

Total performance = Operator Status ➡ Total SMV / Operator Status ➡ Total on standard

Operator Status ➡ Total piece rate

Earned piece rate in total.

Operator Status ➡ Total SMV

Earned SMV in total.

Order ➡ Order

Order Number of the product.

Order ➡ Order Line

Order Line Number of the product.

Product ➡ Extra Data

Show extra data connected to the product. This field is not normally in use.

Product ➡ Fault Code

List of faults code registered on product that have not yet been repaired.

Product ➡ Product

Product Number, can be assigned to products when loading.

Product ➡ Replacement ★

Will show a ★ character when the product is loaded as a replacements to a faulty or 2nd quality product. This is only possible when Replacement Loading is activated.

Production ➡ Loaded

Number of loaded carriers for product order line.

Production ➡ Quantity

Original quantity for the product order line.

Production ➡ Rejected

Number of rejected products on the product order line.

Production ➡ Required quantity

Number of carriers that should be loaded in total. If Replacement Loading is not activated, this is the same as the original quantity.

Production ➡ Second quality

Number of second quality products on the product order line.

Production ➡ Unloaded

Number of unloaded products on the product order line.

Sending Station

Station where this carrier was last sent from, not counting bridges.