Bundle Tracking is the link between the preparation department and the assembly line. It allows you to register operations on products even before they are loaded into the Eton system.

Bundle Tracking can either be used by tracking operations outside the Eton systems, either all operations or only key operations. In both approaches it works by using a bundle client to register operations.

On the Eton system the regular terminals and webclients are connected to a station, but a bundle client can either follow an operator or be attached to a workstation outside the Eton line.

All interaction with the system are done through the Bundle Client; logging in, registering work on operations, viewing production metrics.

Solutions

"Wall to wall" solution:

- Include every single operation in your production. Orders, operations, articles, faults are all tracked to a high level of detail

- Every operation is tracked, which provides good information for all employees to your payroll system

- All products are tracked from start to finish, which gives you good follow up on how the product is progressing even before being loaded onto the Eton production line

- The only equipment needed is one Bundle Client per operation

![]()

"Key operation" solution:

- Covers the most important key operations, for instance known bottlenecks

- Provides good work time information on the tracked operations, on operations in as well as outside the Eton system

- Saves on resources as you only need Bundle Clients for the key operations

![]()

Features

All interaction with the Eton system is handled through the Bundle Client, which can be used on mobile phones, tablets, computers etc.

- The bundle tracking process begins at the bundle loading station where the bundles are divided, given a bundle id and registered with the system

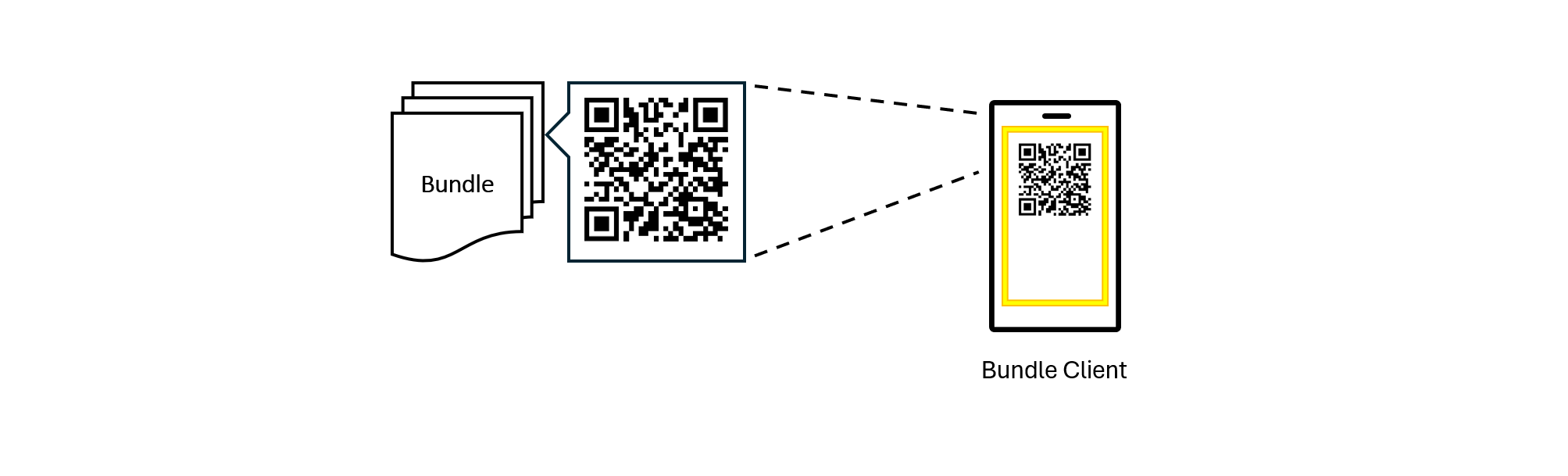

- The bundle gets a physical tag with a QR code, which is then scanned to register it. The code connects the bundle with information about it; quantity, order number, criteria (like color/size etc) and more

- After registering, simply scan a tag to show all information about that bundle on the bundle client. Adjust values, add/remove quantity and so on.

- The system keeps track of employee number (who is working), bundle id (which product), operation (what is performed), quantities (how many pieces). To work on another bundle, simply scan that bundle tag instead

- While operations in a Eton production route are performed in sequence, bundle operations can be done in any order. Bundle operations can still have a sequence, but can be grouped so within the group the order is irrelevant

- The bundle client also handles quality control

Quality control

Quality control is either done at a dedicated inspection station or as part of a supervisors daily task. Either way all interaction goes through the Bundle Client. Scan the bundle tag, register any faults and quantities that needs rework.

- The dedicated quality control is usually a workstation all products has to pass through to either pass or being reworked

- When performed by a supervisor the check can be made for instance at the workstation of the last operation or by making sampling of the products

Transferring

As a last step of the bundling process the products are taken to a loading station and transferred to a carrier in the Eton system.

- In Eton this is set up as a transfer operation from the bundle route to a production route

- Bundles can either be transferred as one single piece to one carrier, several pieces to one carrier or several pieces to multiple carriers

- You can transfer any quantity to carriers, either the whole bundle or a few pieces at a time

- Using the Bundle Client, scan the tag and input which quantities to transfer to each carrier

It is also possible to transfer products from a Eton production route to a bundling process. In some situations it is necessary to perform operations outside the Eton system even after unloading.

- Unload and collect the products from the carriers to a bundle

- Print new tags with QR codes and attach to the bundles

- In the production route, add a transfer to a bundle route operation

- After that transfer the bundle operations are performed the same as in any bundling process