💬 This guide assumes you have completed the basic administration guides as well as the setting up an inspection route guide.

Sampling is used to send a selection of carriers for inspection. How many carriers are sent is determined by several optional factors. It is discussed in greater detail on Topic: Sampling but to summarize you can set a percentage on operations, operation groups, users and user groups.

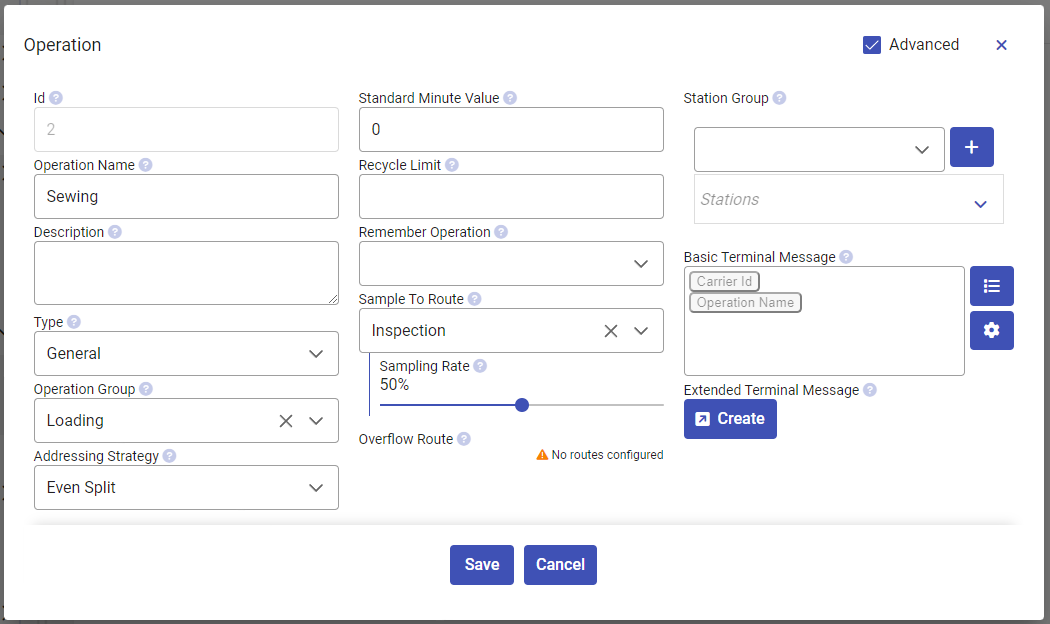

Let's set up sampling on our sewing operation so that on average every second product will be inspected completed sewing.

Creating the Sampling Route

- A sampling route is just an inspection route, if you have followed the previous guide you will have an inspection route named "Inspection".

Setting the Sampling Rate

- Navigate the menu to Administration > Operations > Operations.

- Select the "Sewing" operation in the list, then press 📝 to begin editing the operation.

- Make sure the "Advanced" checkbox is ticked

- In the "Sample to Route" dropdown, select "Inspection".

- Set the sampling rate slider to 50%.

- Click Save

Tips

💡 The system decides if it should send to sampling or not by "rolling the dice" after an operation has completed.

💡 To perform the sampling, just follow the same steps as for a normal inspection.

💡 If the sampling station is full, the sampling will be skipped, even with a 100% sampling rate.

💡 Sampling may also be set on an operation group, a user or a user group. The steps are very similar to setting up sampling on an operation.